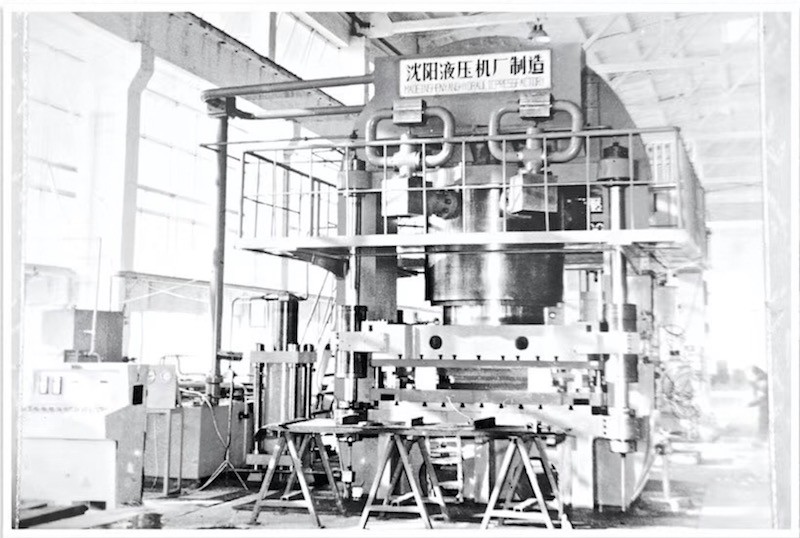

This 20,000 ton heat exchanger press frame is made by wire winding production technology in SYHP factory. The major material of the frame is big casting steel. The wire winding technology use hundreds of miles high strong steel wire instead of traditional several posts or welding method connect these major big parts together. There is no stress concentration in wire winding steel, so the working life of the frame is much longer time. In addition, the size of frame is much smaller than traditional designing (more than 30% material saving). The robot car will do the wire winding around frame automatically for one month in one 20,000 ton frame. In the meantime, the computer tests the wire stress to meet the designing requirements.

For over 30 years, we have made hundreds sets of more than 3000 ton wire winding hydraulic presses. The first 10,000 ton wire winding hydraulic press in 1985 is still reliable working now. Now the big national project in China such as 68,000 ton forging press, 40,000 ton forging and 36,000 ton extruding press all adopt this technology to make the machine more reliable, precision and much smaller size. This type of technology is very suitable for production application of high pressure pressing forming under small working table size. Welcome to visit us and see wire winding world!

www.syhpress.com

info@syhpress.com

Shenyang Heavy Forge Hydraulic Press Manufacturing Co., LTD

First 10,000 ton wire winding hydraulic press made by SYHP in year 1985